Many types of machines are used in industries both indoors and outdoors. This machinery can be very expensive. Each one is going to perform a very specific task. From the machinery that you would find inside of a workshop to machines for combining particulates, they are necessary for many industries. The cost of these machines, and their overall design, has changed significantly over the years. Here are some of the most common types of expensive machinery that are used today.

Grinding Machine

These machines are specifically designed for grinding materials into particulates. These are used in the mining industry to extract valuable metals. This may include silver, gold, and other minerals. In most cases, the material will be removed in a systematic way. They are often use bonded cutting edges. There is often a drum where the material is placed inside and a screen and a dust exhaust system.

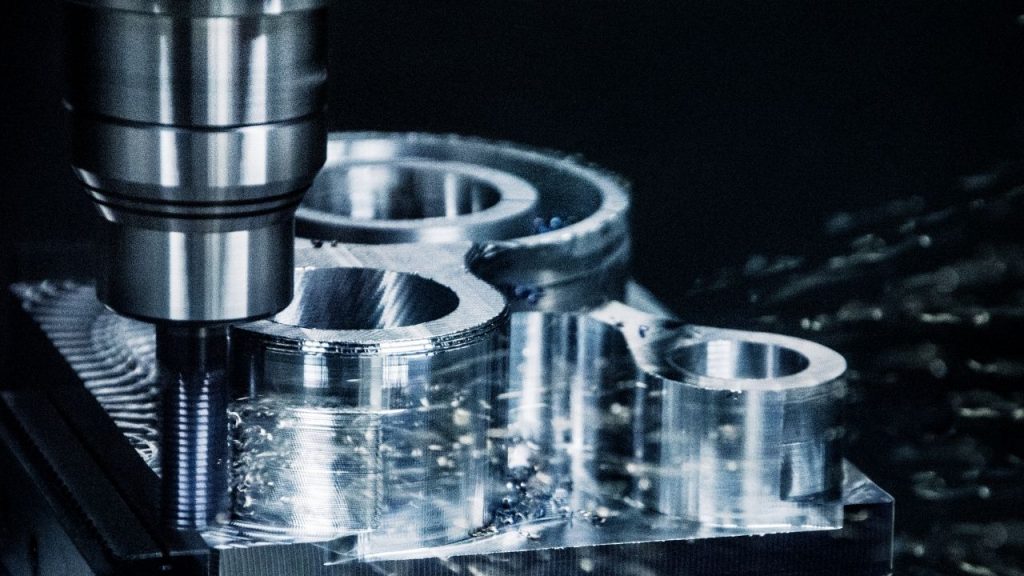

CNC Milling Machines

Computer numerical control machines are one of the most advanced machines on the planet. They are designed to transform various types of raw materials by adding or removing materials from the initial batch. If used for the milling process, you can utilize this for creating products made from wood or metal. They will use a milling cutter which is a cylindrical tool that is held on a spindle.

Metal Lathe Machine

A metal lathe is a machining machine used to make parts using metal. It works by inserting a metal stock into a spindle that rotates at a specified speed. A set of cutting bits is mounted in a toolpost and held rigidly in place by a toolpost. The cutting bit is controlled by a carriage mechanism that moves along the bed of the machine. The workpiece is centered by a cross slide or a compound rest.

Multitasking Machines

As the name would indicate, these are machines that will combine two or more different machines that will perform a specific task. This is often used for milling different items that will require some form of multitasking. Use for both milling and turning projects, and these machines can help you reduce the number of machines that you need to use one after the other. They will be equipped with an automatic tool changing function that can assist you with grinding, turning, or milling for any industrial project.

Drill Press

A drill press is a tool that uses a drill bit that is connected to a check. They are manually used, allowing the user to move the drill bit up and down. Although these are used for drilling holes through wood, you can also use them for going through steel. They are often connected to a single spindle, or they may be a belt-driven machine that is floor mounted that is designed for multiple purposes.

Welding Machine

A welding machine, along with welding guns, is necessary for the metal industry. If you have ever connected to or more pieces of metal, this was done with a welder. They are capable of generating a substantial amount of heat courtesy of an acetylene tank that is nearby. This will provide the fuel needed to create the flame from the welding device that will melt and connect the metal. There are different types of welding machines, including arc welding machines and those designed for hot-dip brazing and resistance welding as well. There are also new machines that use electron beams and lasers, which are extremely efficient.

Machine Tool

The purpose of a machine is for grinding, boring, cutting, and shearing different types of metal. There is also the possibility of shaping the metal into very specific sizes. You can do this automatically or freehand, depending upon what you are making. Machine tools, just like cutting tools, will allow you to create many different products that can be used for various projects.

Planer

Primarily used in a woodshop or similar setting, they are designed for working with lumber. The purpose of a planer is to create a smooth cut that goes along the length of the workpiece, such as a door hanger. It is a tool that is based on a jointer, which is another tool found in a shop. A jointer is equipped with adapters, and most planers have a bench-mounted base. This will allow the planer to be operated in an inverted position.

All of these tools can be very expensive. They are designed to create very specific types of products. Whether you are working with metal or lumber, each of these tools can speed up the process of completing your project. If you are working with metal, grinding machines, CNC milling machines, and a metal lathe may be needed. If you are working with wood, the planer and standard machine tool will certainly suffice. When choosing these tools, be sure to obtain them from a reliable source. If you need more information about these types of machines, visit our website today.